Products

- Details

- Category: Products

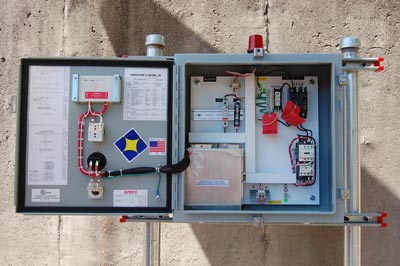

Sidesloper® pre-engineered packages are designed to utilize a basic Sidesloper® control panel with either flat switches or a pressure transducer along with a Sidesloper® pump. The control panels are designed to provide automatic pump operation for both side slope and vertical wet well applications.

The Sidesloper® GC100 model utilizes a pressure transducer and a digital controller to provide reliable automatic operation and constant monitoring of sump level. Much like its bigger brother the GC101 it utilizes dependable independent components to allow for years of service and is easily serviceable.

- Reliable design

- Intrinsically safe

- Level display allows for level setting adjustments

- Weather tight 16-gauge Steel NEMA 4

- enclosure

- Optional NEMA 4X stainless steel enclosure available

- Optional dead front enclosure with interior door mounted controls and 180° opening door for easy operator access.

- Sturdy 30mm operator controls

- Operator flash safe

- Provides motor short circuit and overload protection

- Elapsed Time Meter (hour meter)

- Auxiliary start relay for extended level indicator life

- Control transformer provided on three phase models

- Spare fuses and bulbs provided

- Daylight LED high level alarm beacon

- UL rated

The Sidesloper® GF100 model utilizes a series of float switches to provide reliable automatic operation of a pump in a vertical wet well sump. Much like its bigger brother the GF101 it utilizes dependable independent components to allow for years of service and is easily serviceable.

- Simple Design

- Intrinsically safe

- Works with affordable common float switches

- Weather tight 16-gauge Steel NEMA 4 enclosure

- Optional NEMA 4X stainless steel enclosure available.

- Optional dead front enclosure with interior door mounted controls and 180° opening door for easy operator access.

- Sturdy 30mm operator controls

- Operator arc flash safe

- Provides motor short circuit and overload protection

- Elapsed Time Meter (hour meter)

- Auxiliary start relay for extended level indicator life

- Control transformer provided on three phase models

- Spare fuses and bulb provided

- Daylight LED high level alarm beacon

- UL rated

- Details

- Category: Products

GunnCo maintains a large inventory of replacement and spare parts for Sidesloper® pump systems that are available for same day shipment in most cases, such as:

- Sidesloper® Control Panels

- 4” and 6” Teflon® Fitted Submersible Pump-Ends

- 4” and 6” Submersible Motors

- Jacketed Power Cables

- Level Transducers

- Phase and Voltage Monitors

- Intrinsically Safe Relays

- Surge Protection Devices

- Level Indicating Pump Controllers

- Motor Starters

- Single Phase Modules

- Float Switches

- Motor Run Protection Devices

- High Level Alarm Lights

- Junction Boxes (Break Out Boxes)

- Wireless Transmitters and Receivers

- Patented Sidesloper® Wheeled Carriers

- Control Panel Mounting Racks

- Junction Box Mounting Racks

- Flexible Cable Seals

- Stainless Steel Safety Cables

- Pipe Supports

- Sun Shields

- Panel Roofs

- Flow Meters

GunnCo also stocks a wide variety of stainless steel fitting and other miscellaneous parts that are required to maintain safe operation and compliance such as:

- Quick Disconnects

- Exit Fittings

- Pitless Adapters

- Ball Valves

- Check Valves

- Flanges

- Unions

- Tee Fittings

- Pipe Nipples

- Pipe Elbows

- Caps

GunnCo also has a wide variety of accessories available.

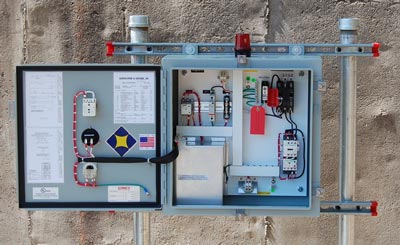

Sidesloper® control panels are available as simplex, duplex, triplex, dual, and even custom combination panels such as alternating duplex, dual, and duplex/simplex combinations. Sidesloper® control panels can use pressure transducers, floats, or bubblers for automatic operation. Our control panels use heavy duty independent control units for reliable operation and quick, easy service. Simple manual control panels are also available.

- Simplex/Duplex/Triplex/Dual/Custom

- Transducer/Float/Bubbler/Manual

- Level Alarms

- Solar Level Indication and Alarm

- Wireless Signaling

- SCADA Ready

- Flow Meters

- Load Sensing

- Sequestered Arc Proof Panels

Sidesloper® GC Series Control Panels utilize pressure sensing submersible transducers and provide precise level indication to 1/10th of an inch for side slope applications and most vertical applications. Sidesloper® GC series control panels feature:

- User friendly level indicating controller provides liquid level to 1/10th of an inch. Standard range is 0 to 138.6". Level settings are easily checked with a turn of a knob and are equally simple to change by turning a small adjustment screw on the face of the indicator-no punch and scroll as required by competitive manufacturers.

- Pressure level sensor with surge suppressors for extended warranty against damage due to surge events. Intrinsically safe barriers with internal fuses are standard.

- A large view window allows operator to monitor level, flow, totals and status without entering the enclosure.

- A three-point latching mechanism with a heavy stainless steel handle with lock hasp is standard equipment on Sidesloper® control panels. This latch allows quick and easy access and ensures proper closure and sealing of panel.

- Interior door opens 180 degrees with mounted controls that include:

- A main breaker disconnect safety switch

- Heavy duty NEMA rated motor and control breaker

- Heavy Duty 30 mm operation status indicating lights

- H-O-A control switch for operator safety

- Elapsed Run Time Meter

- Motor Overload Reset Push Button

- Standard system includes five surge protection devises:

- Primary Surge Protection Device

- Incoming voltage/surge monitor

- Control circuit surge suppressor

- Level signal surge suppressor

- Level sensor surge suppressor

- Optional flow meter provides simultaneous digital display of rate of flow and total gallons pumped up to 99,999,999 gallons.

- Optional remote lock out feature allows the pump to be disabled via a pair of 14 AWG wires up to 5,000 feet away. Design allows standard panel to be easily upgraded to lock out option.

- Optional wireless remote lockout option available.

- Optional top alarm light or high visibility strobe light available.

- All panels include spare bulbs and fuses standard for convenient correct field replacement.

- Custom features provided upon request.

Sidesloper® GF Series Control Panels utilize traditional float switches which provide reliable and lower cost service in vertical well applications. Sidesloper® GF series control panels feature:

- Heavy Duty NEMA 4X weather tight enclosures constructed of stainless steel to provide maximum service life. Sidesloper® panels can also be provides in coated steel or non-metallic enclosures for cost savings.

- A large view window allows operator to monitor level, flow, totals and status without entering the enclosure.

- A three-point latching mechanism with a heavy stainless steel handle with lock hasp is standard equipment on Sidesloper® control panels. This latch allows quick and easy access and ensures proper closure and sealing of panel.

- Interior door opens 180 degrees with mounted controls that include:

- A main breaker disconnect safety switch

- Heavy duty NEMA rated motor and control breaker

- Heavy Duty 30 mm operation status indicating lights

- H-O-A control switch for operator safety

- Elapsed Run Time Meter

- Motor Overload Reset Push Button

- Standard system includes five surge protection devises:

- Primary Surge Protection Device

- Incoming voltage/surge monitor

- Control circuit surge suppressor

- Level signal surge suppressor

- Level sensor surge suppressor

- Heavy Duty, self-weighted, mechanical or mercury floats are used for automatic control of pumps.

- Optional flow meter provides simultaneous digital display of rate of flow and total gallons pumped up to 99,999,999 gallons.

- Optional remote lock out feature allows the pump to be disabled via a pair of #14 wires up to 5,000 feet away. Design allows standard panel to be easily upgraded to lock out option.

- Optional wireless remote lockout option available.

- Optional top alarm light or high visibility strobe light available.

- All panels include spare bulbs and fuses standard for convenient correct field replacement.

- Custom features provided upon request.

Sidesloper® GB Series Control Panels utilize a bubbler level transmitter eliminating the need to use a submersible pressure transducer. The bubbler level transmitter is an automatic bubbler type liquid level measurement system (Bubbler level transmitter can be added to existing systems as well). It operates by forcing compressed air into a bubbler tube at a constant rate with its opening placed near the bottom of the liquid. The bubbler level transmitter measures the pressure required to force air through the tube and generates a 4-20 mA signal which is proportional to the depth of the liquid. This is ideal for applications where leachate temperatures exceed 140°F. Sidesloper® GB series control panels feature:

- Heavy Duty NEMA 4X weather tight enclosures constructed of stainless steel to provide maximum service life. Sidesloper® panels can also be provides in coated steel or non-metallic enclosures for cost savings.

- A large view window allows operator to monitor level, flow, totals and status without entering the enclosure.

- A three-point latching mechanism with a heavy stainless steel handle with lock hasp is standard equipment on Sidesloper® control panels. This latch allows quick and easy access and ensures proper closure and sealing of panel.

- Interior door opens 180 degrees with mounted controls that include:

- A main breaker disconnect safety switch

- Heavy duty NEMA rated motor and control breaker

- Heavy Duty 30 mm operation status indicating lights

- H-O-A control switch for operator safety

- Elapsed Run Time Meter

- Motor Overload Reset Push Button

- Standard system includes five surge protection devises:

- Primary Surge Protection Device

- Incoming voltage/surge monitor

- Control circuit surge suppressor

- Level signal surge suppressor

- Level sensor surge suppressor

- A dual compressor bubbler lever transmitter will be provided to generate 4-20 mA signal for level indication.

- User friendly level indicating controller provides liquid level to 1/10th of an inch. Standard range is 0 to 138.6". Level settings are easily checked with a turn of a knob and are equally simple to change by turning a small adjustment screw on the face of the indicator-no punch and scroll as required by competitive manufacturers.

- Optional flow meter provides simultaneous digital display of rate of flow and total gallons pumped up to 99,999,999 gallons. Optional remote lock out feature allows the pump to be disabled via a pair of #14 wires up to 5,000 feet away. Design allows standard panel to be easily upgraded to lock out option.

- Optional wireless remote lockout option available.

- Optional top alarm light or high visibility strobe light available.

- All panels include spare bulbs and fuses standard for convenient correct field replacement.

- Custom features provided upon request.

Sidesloper® GM Series Control Panels utilize manual switch to operate pump or pumps. Typical applications include truck fill and areas with very little rain fall. Can be used for sideslope, vertical, and any other pump application.

- Heavy Duty NEMA 4X weather tight enclosures constructed of stainless steel to provide maximum service life. Sidesloper® panels can also be provides in coated steel or non-metallic enclosures for cost savings.

- A large view window allows operator to monitor level, flow, totals and status without entering the enclosure.

- A three-point latching mechanism with a heavy stainless steel handle with lock hasp is standard equipment on Sidesloper® control panels. This latch allows quick and easy access and ensures proper closure and sealing of panel.

- Interior door opens 180 degrees with mounted controls that include:

- A main breaker disconnect safety switch

- Heavy duty NEMA rated motor and control breaker

- Heavy Duty 30 mm operation status indicating lights

- H-O-A control switch for operator safety

- Elapsed Run Time Meter

- Motor Overload Reset Push Button

- Standard system includes five surge protection devises:

- Primary Surge Protection Device

- Incoming voltage/surge monitor

- Control circuit surge suppressor

- Level signal surge suppressor

- Level sensor surge suppressor

- Optional pressure transducer or dual compressor bubbler lever transmitter will be provided to generate 4-20 mA signal for level indication.

- Optional digital level indicating display (requires level transducer or level transmitter).

- Optional flow meter provides simultaneous digital display of rate of flow and total gallons pumped up to 99,999,999 gallons.

- Optional remote lock out feature allows the pump to be disabled via a pair of #14 wires up to 5,000 feet away. Design allows standard panel to be easily upgraded to lock out option.

- Optional wireless remote lockout option available.

- Optional top alarm light or high visibility strobe light available.

- All panels include spare bulbs and fuses standard for convenient correct field replacement.

- Custom features provided upon request.

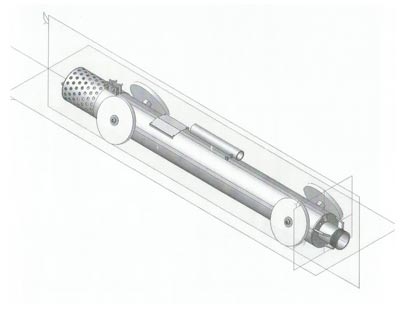

Sidesloper® Pumps utilize a patented stainless steel wheeled pump carrier or a full length stainless steel perforated screen. Sidesloper® pumps are engineered and manufactured by GunnCo specifically for landfill leachate removal and control applications. Our side slope model has several unique and patented features such as: a skid plate on both ends that allow pump to jump over weld beads for easy installation and service; an external pressure transducer holder that is located even with the pump inlet to minimize the chance of damage to the pump being run dry and allow for service without removing the pump and motor. Our vertical model incorporates an easily removable pump for serviceability and a full length protective screen to allow for longer service periods before cleaning is required.

The Sidesloper® patented stainless steel wheeled carrier is engineered specifically for side slope riser applications. Sidesloper® pumps have several unique and patented features that allow for superior performance in landfill environments such as: a skid plate on both ends that allow pump to jump over weld beads for easy installation and service; an external pressure transducer holder that is located even with the pump inlet to minimize the chance of damage to the pump being run dry and allow for service without removing the pump and motor. Field service is a breeze due to its easily removable pump and can be done of the tailgate of a truck in most cases.

- Pumps are 304 SS with Teflon® seals (316 SS available)

- Multistage pump design allows for compact size

- Pumps range from 5 GPM to over 1000 GPM with ½ to over 20 horsepower motors

- Low profile allows operation in 18” to 24” riser pipes

- Can be customized for smaller or larger riser pipes depending on your specific applications

- Components design makes maintenance quick and easy.

- Provides proper motor cooling

- Patented removable inlet screen stops debris from entering the internal pump suction screen

- Screen is easily removable for service

- Discharge head makes removing the pump and motor from the carrier easy

- Large wheels roll over welding beads common to HDPE riser pipe construction

- Patented skid bars provide an extra level of reliability in positioning pump

- Protective transducer holder “piggy-backed” to the carrier body allows easy access

The Sidesloper® perforated stainless steel screen is engineered for vertical wet well applications that have a large amount of debris in them. Sidesloper® perforated screens allow for longer periods of service before they need to be cleaned while protecting the pump from damage caused from debris getting into the pump itself. Field service is a breeze due to its easily removable pump and can be done off the tailgate of a truck in most cases.

- Developed for 2 HP and smaller vertical applications.

- Minimizes the chance of debris entering the pump.

- Used where shavings and debris may be present particularly in gas condensate dewatering sumps.

- Large open area extends operating periods.

- Available in 1”, 1.25”, 1.5” and 2.0” discharge sizes.

Call today for sales, service, parts, or more information.

515 Industrial Way

Cumming, GA 30040

770-889-7114 phone

770-889-2754 fax

info@gunnco.com email

About GunnCo

GunnCo Pump & Control, Inc. is a family-owned business located just north of Atlanta. Mike Gunn and his experienced staff represent over 50 years of pump design, construction, and application experience, offering landfill pumps and related equipment packages, as well as singular components: pumps, custom controls, replacement parts, and accessories for all pumping systems.