Sidesloper® Vertical Wet Well - Section 5

- Details

- Category: Sidesloper® Vertical Wet Well - Section 5

P2K Pumps

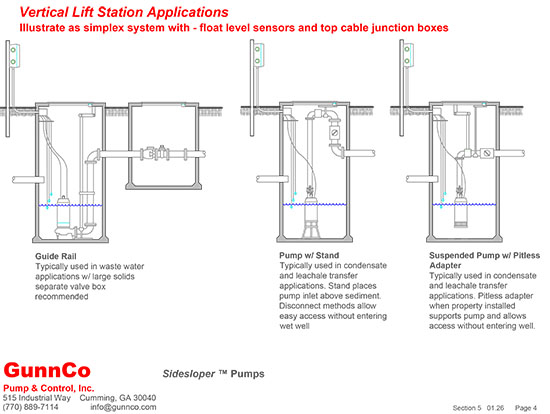

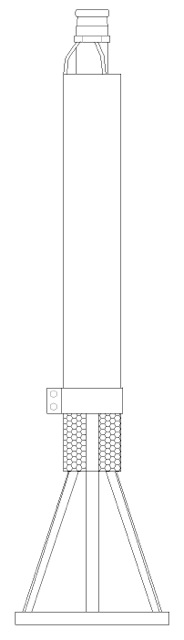

The P2K series pumps may be used for vertical wet well applications. The vertical pump would include a "V" version (such as P2KV _____) which does not have wheels. The pump is mounted in a stainless cooling sleeve with an inlet strainer and is often provided with a quick disconnect assembly for easy removal and installation. GunnCo offers an inlet stand to elevate the pump above the floor of the wet well as sediment tends to build up in a wet well over time and eventually the wet well may need cleaning to remove.

The P2K series pumps may be used for vertical wet well applications. The vertical pump would include a "V" version (such as P2KV _____) which does not have wheels. The pump is mounted in a stainless cooling sleeve with an inlet strainer and is often provided with a quick disconnect assembly for easy removal and installation. GunnCo offers an inlet stand to elevate the pump above the floor of the wet well as sediment tends to build up in a wet well over time and eventually the wet well may need cleaning to remove.

Another arrangement is to suspend the pump so it is about a foot off the floor of the well.

Pumps under 2 H.P. may not require a cooling sleeve for operation. This is important in applications where the pump may be installed in clean out pipes or small dewatering casings.

Another option is an extended strainer housing which can be provided where there are excessive debris materials, particularly in applications where the stream may contain include shavings from HDPE pipe fabrication.

The P3K Series may handle silts better and The P3KH includes an anger to feed the solids into the impeller. GunnCo also offers true waste water pumps designed for handling sewage for applications that might include other waste streams.

Use of guide rail systems is another option and should be carefully considered with service in mind and are determined by the pump selection. Under no circumstances should a pump be installed that requires entry into the hazardous wet well for maintenance.

Many vertical wells use an alternating duplex pump arrangement.

Most vertical installations do not require indicating level control panels and may use a float based level controller. Simplex and duplex panel specifications are provided in Section 4.

Typical system specifications for vertical applications are available from GunnCo upon request.

We offer self-priming and various types of electric submersible pumps. Pumps and complete packages with sumps are available from GunnCo.

- Details

- Category: Sidesloper® Vertical Wet Well - Section 5

1.01 PUMP

-

The pump shall be a GunnCo Sidesloper TM P2KV ________.

-

Impeller shall be constructed of stainless steel including housing, impellers,

bowls, check valve disc, shaft, coupling, and strainer.

-

Bearings and seal rings shall be constructed of stainless steel and Teflon material.

-

Pump shall provide a flow of _____ GPM at a discharge pressure of ______ feet of head.

The pump shall be a model P2KV _______

1.02 MOTOR

-

The motor shall be a ______ HP non-overloading for the duty specified and shall be suitable for operation on [single phase 230] [three phase 230] [three phase 460] volt power.

-

Motor shall be permanently lubricated and constructed of stainless steel wetted parts with stainless steel clad or corrosion resistant end housings.

-

Power cable shall be heavy duty submersible type, continuous length, and sized per U.S. NEC standards. A strain relief/riser exit fitting shall be provided. Cable length shall be ______ feet. (Typical wet well depth plus 15 ft. minimum)

1.03 COOLING SHROUD

-

Pump and motor shall be mounted in a cooling shroud constructed of stainless steel. A removable inlet strainer basket reinforced to carry the weight of the pump assembly shall be provided.

-

The cooling shroud shall be equipped with a welded stainless steel ring for connection of a Lifting cable. Cable and fitting shall be [3/16] [1/4] minimum diameter.

-

The safety/pull cable shall be stainless steel and a minimum of ____ feet long. The cable shall be provided with stainless steel u-bolt type clamps. A stainless steel removable link and a stainless steel upper snap hook and anchor eye bolt. All fittings shall be rated at least three times the pump assembly weight.

D. A discharge quick release fitting at the bracket shall be provided.

Call today for sales, service, parts, or more information.

515 Industrial Way

Cumming, GA 30040

770-889-7114 phone

770-889-2754 fax

info@gunnco.com email

Sidesloper® pumps are designed for use in side slope riser applications or may be provided without wheels for use in vertical sump applications where cooling or lower inlet screens are required.

Sidesloper® pumps utilize the highest quality materials and components available for long and reliable service life.